Types Of Printing

Types Of Printing at U-Pack™

Comparison of Printing Techniques on Cardboard Boxes

Being new to printing could be an overwhelming experience, especially if you do not have any knowledge of the printing industry and the different types of printing services. All of these services have their pros and cons. There are some types that are perfect for short print runs while there are some types that are best suited for low-volume runs.

Choosing the perfect printing service can be a little difficult and confusing at times. This is why we have given a comprehensive guide that will help you understand the different types of printing and their costs.

This guide provides an overview of four common printing techniques used on cardboard boxes and other paper based packing materials: flexographic, offset / lithographic, digital, and screen printing. Let's dive right in!

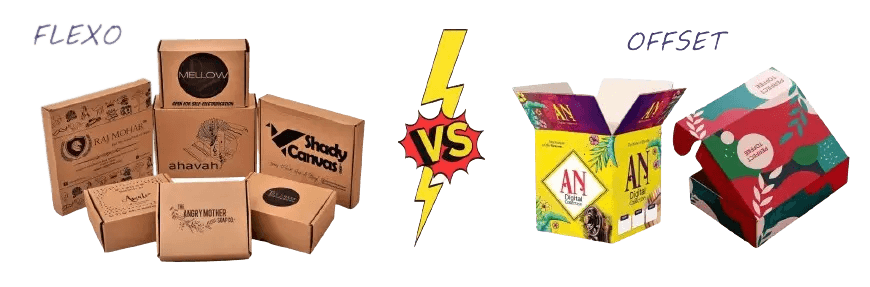

Flexographic Printing

Flexographic Printing

Pros:

- Cost-effective: Flexo printing is economical when scaling up, as the more you print, the lower the cost per unit.

- Fast production speed: Offers quick setup and high-speed printing capabilities.

- Versatility: Can use a wide range of inks and can print on various substrates including large corrugated cardboard.

Cons:

- Initial setup cost: High initial costs due to the need for custom-made printing plates.

- Limited detail: Not ideal for designs that require fine detail or complex images.

- Limited colours: No colour gradient/shading and for two colour jobs registration is +/- 5 mm.

Offset Printing

Pros:

- High image quality: Produces sharp and clean images and typefaces.

- Cost-effective for high volumes: Per-unit cost decreases significantly as the quantity increases.

- Color accuracy: Excellent color control and consistency across the print run.

Cons:

- Not suitable for short runs: The setup process is lengthy and costly, making it less economical for small batches.

- Setup time: Longer preparation time due to plate creation and ink setup.

- Sheet Size Limitations: Usually the sheet sizes are limited to 28x40" making it difficult to print larger boxes.

Digital Printing

Pros:

- Quick turnaround: Minimal setup time, making it ideal for urgent and short runs.

- Customization: Easy to customize each print without additional costs or time.

- Cost-effective for small batches: No need for plates allows for economical small runs.

Cons:

- Cost per unit: Higher cost per unit compared to offset and flexo for large volumes.

- Limitations on substrates: Not all digital printers can handle very thick or uneven substrates like corrugated cardboard.

- Sheet Size Limitations: Usually the sheet sizes are limited to 13x20" making it suitable only for small boxes.

Screen Printing

Pros:

- Vibrant colors: Thick ink application results in bright, vibrant colors even on darker boxes.

- Durable: Prints are very durable and resistant to external factors such as water and UV light.

- Material versatility: Can be used on a variety of materials, including uneven surfaces.

Cons:

- Labour-intensive: More manual process compared to other printing methods.

- Not cost-effective for large volumes: Slower production rate and higher labor costs make it less ideal for large orders.

Pro Tips for great results:

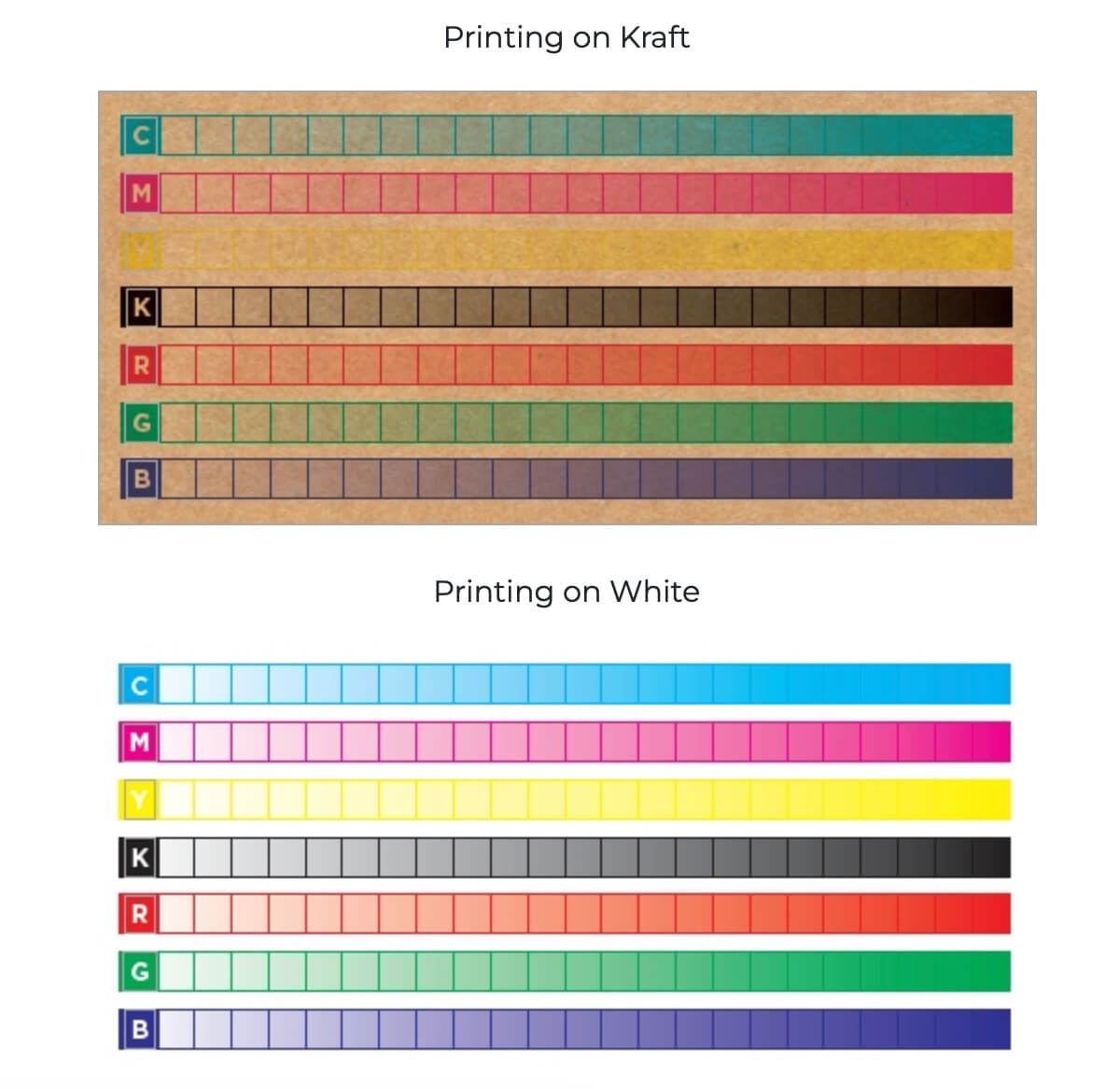

When choosing between Kraft and white substrates for packaging, it's important to consider how they affect ink colors. White substrates provide a clear, neutral base, allowing colors to appear vibrant and true. This is ideal for designs with light colors and detailed graphics.

Kraft substrates, however, offer a natural, rustic look but can alter color appearances due to their brown color. Light colors like pastels may not print well on Kraft, appearing muted or different than intended. White ink also does not show on Kraft; any white in the design will appear as the original brown of the Kraft material.

For designs needing accurate color reproduction or featuring white, opt for white substrates. If a natural look is preferred, Kraft is suitable, though it's best for darker colors.

- Image Resolution: Please provide all images at 300ppi (pixels per inch) at final size for best print quality. If an image is uploaded at 300ppi and then increased in size, its resolution quality is reduced.

- Safe Print Area: Keep all elements 1/8” from folds and cuts.

- Text and Line Sizes: 0.5 pt Minimum for Lines & 8.0 pt Minimum for Text.

- Artwork And Text Orientation: Remember that each panel is going to fold and your artwork or text must orient correctly when assembled.

- Embossing, Debossing & Foil Stamping: Contact us for these services.